The digital solution for fabrication, supporting industrial projects, operations and maintenance.

> MODS Connect Fabrication futureproofs your fabrication business with transparent, accessible real-time information <

> MODS Connect Fabrication

MODS Connect Fabrication is a progressive solution to longstanding fabrication challenges, including traceability and progress tracking.

The demands of industrial digital transformation are pushing fabricators towards increased transparency, accuracy and accessibility of up-to-date information. This requires digitalizing and centralizing all fabrication information.

> Fabrication management challenges <

Information gaps regarding fabrication progress have downstream supply-chain implications, compromising the efficient construction execution, operation and maintenance of complex facilities.

-

Unknown real-time information status

-

Lack of traceability

-

Compromised quality assurance

-

Difficulties tracking Heat Numbers

-

Incident troubleshooting delays

-

Managing cumbersome paper-based systems

-

No accountable tracking of fabricated components

> Digital fabrication management improves <

> Efficiency

> Cost

> Scheduling

> Productivity

> Traceability

> Communication

> MODS Connect Fabrication benefits

-

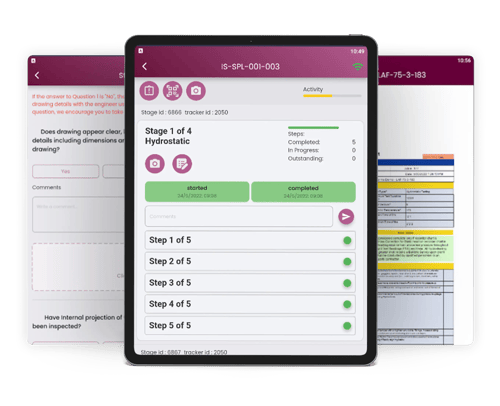

Real-time fabrication tracking via app technology

-

Dashboard and static reporting

-

Quick traceability

-

Digital fabrication dossiers

-

Improved transparency

-

Supply-chain visibility of fabricated components

-

Reduced administration

-

Improved scheduling

-

Clearer, more accurate communication

-

Heightened quality assurance and accountability

> Digitalize your fabrication processes

Digital transformation in industrial sector projects, operations and maintenance is on the rise, yet fabrication record keeping still tends to rely on stacks of paper.

A digital solution now exists that ensures transparent and traceable fabrication processes, aligning this critical project phase with trending best practices used by construction contractors and operators.

Fabrication generates a high volume of information. Using digital technology such as QR codes from the earliest possible stages eliminates the need for unwieldy paper-based processes.

When system-ready, digitalized, centralized and navigable, fabrication data is powerful. Our progressive digital fabrication solution brings real-time status of fabricated components to your fingertips, anytime and from anywhere.

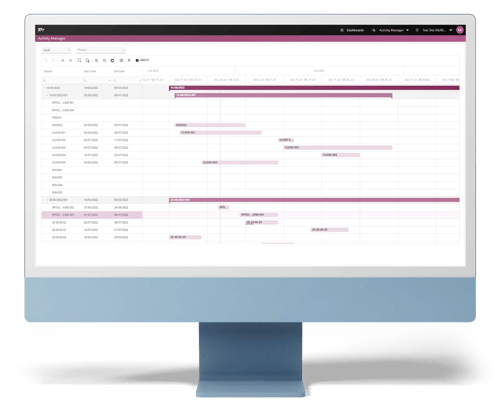

> Streamlined progress tracking

Being able to track the fabrication process is essential to meeting the needs of digital transformation in the construction, operation and maintenance of complex facilities.

The way to achieve this is through digital progress tracking, an innovative and much-needed approach.

Our easy-to-use solution helps you keep a handle on activity status and ensures fabrication progress syncs with project priorities and status. When fabricators are on the same page as construction contractors or operators, projects run smoothly, on time and under budget.

> Traceability

Effective incident tracing to troubleshoot and mitigate subsequent issues demands that fabrication information be accessible, accurate and searchable. In our digital fabrication solution, all fabricated components’ heat numbers are logged in one comprehensive database. With a few keystrokes on a computer or handheld device, all relevant fabrication information is at the ready.

Searching for archival information in reams of paper-based fabrication dossiers is time-consuming and frustrating, especially when trouble-shooting an incident that requires immediate and reliable insights. With MODS Connect Fabrication in place, every heat number is logged and easily traced, even remotely. This eliminates time and stress of mining massive hard-copy files for complete supply-chain information.

> Supply-chain visibility

Sharing and receiving accurate information among global teams requires information to be up to date and at the ready, anytime and from anywhere. With MODS Connect Fabrication, you can view fabrication progress and the projected fabrication schedule.

Our digital fabrication solution affords construction contractors, operators and fabricators to work harmoniously towards optimal efficiency. This ensures that all components are fabricated on time and shipped to the appropriate location by the required time, with easily accessible, quality-assured records in tow.

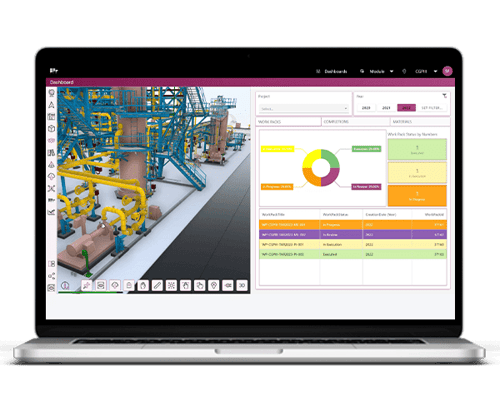

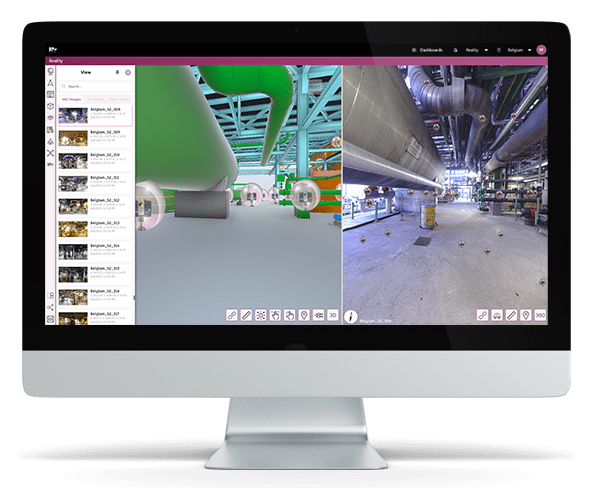

> Take project visualization further with Connect Viewer

Use MODS Connect alongside Connect Viewer for advanced 2D, 3D, point-cloud, and 360° visualization across every phase of your industrial asset’s lifecycle.

Connect Viewer acts as a centralized visual environment, bringing inspection, engineering, construction, and facility data together—fully integrated with your existing ERP and CMMS systems for seamless reporting and real-time decision-making.

"We have a long-standing relationship with MODS and provide them with working insights to develop digital solutions that will benefit businesses like ours. We are pleased to see the official launch of MODS Connect Fabrication, a solution we are already familiar with. We were happy to assist in the beta testing of a fit-for-purpose solution for fabrication yards, helping us enter the next era of digital transformation to make fabrication yards even safer and more productive."

Mark Pregeant

CEO, GIS

> Digitalize your fabrication processes

for operational excellence <

As part of a cloud-based system, MODS Connect Fabrication provides an affordable and easily adoptable, automated solution. The system enables users to interact directly with the online database to efficiently track each activity, reducing costs and institutionalizing operational excellence through the following:

-

Fabrication tracking

-

Supply-chain visibility

-

Global collaborations

-

Dependable traceability

-

Remote-work enablement

> MODS Connect Fabrication functions <

-

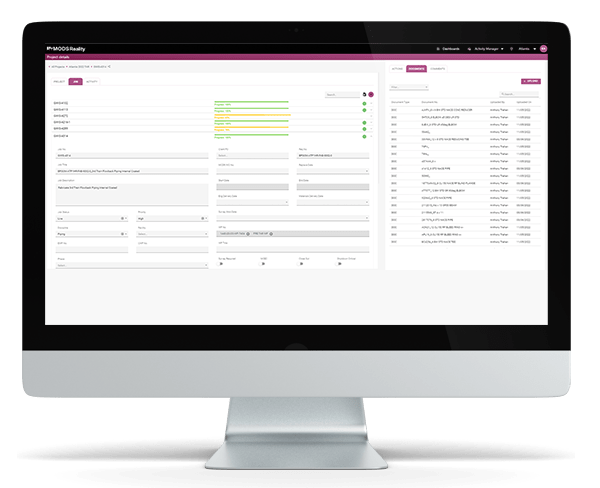

Intuitive activity grid interface

-

Excel import/export

-

Auto QR generation and printing

-

Digital forms eliminate paper-based Quality Assurance workstreams

-

Automatic creation of fabrication dossiers

-

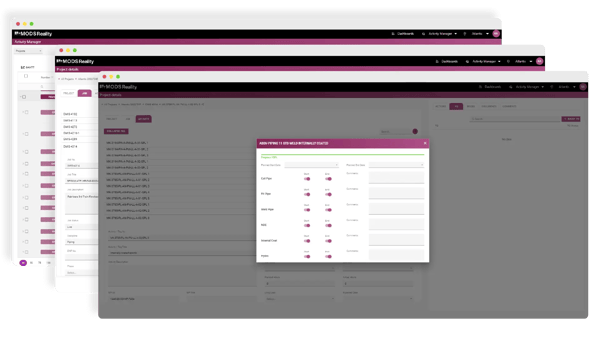

User roles and permissions

-

Dashboard and static reporting

-

Amenable to query for traceability, scheduling and remote oversight

-

Customizable Progress Tracking

-

Document storage and revision control

-

Advanced planning tools and resources (e.g. Gantt charts)

-

Full business integration via web and mobile apps

-

Link to visualization platform

> We would love to talk to you about

our digital fabrication solution <

MODS offers a digital fabrication solution, which is part of the MODS Connect suite. This drives automation of your supply-chain oversight, helping fabricators better align with your project phases. MODS Connect Fabrication gives you the ability to perform rapid incident tracing and to link with materials management systems as well as 3D project visualization. You will have live access to all essential fabrication information, supporting the delivery of projects on time and on or under budget.

Contact the MODS team to arrange a presentation on how MODS Connect can help your organization.

> USE THE FULL CONNECT SUITE FOR HIGHER ROI <

> MODS Connect Fabrication

MODS Connect is the overarching suite of software built for the specific challenges faced by EPC contractors and owner-operators on brownfield projects. As part of this software package, our Fabrication module digitalizes your upstream processes so that real-time activity status is accurate, accessible and traceable, removing data silos once and for all.

Our Fabrication module can also function as a stand-alone software. For a significant return on investment, we recommend looking at the full MODS Connect suite, suitable for brownfield projects of any size.

> Download our Fabrication Brochure <

MODS Connect Fabrication ensures fabrication processes are optimized for your greatest ROI. Download our brochure to learn more about MODS Connect Fabrication functionality and benefits, including:

-

How fabrication software helps with supply-chain visibility, status updates and traceability.

-

How software for fabricators facilitates global collaborations and remote working.

-

How fabrication software solutions impact downstream workflows.