Customizable and scalable, Fab Tracker solves the most pressing fab yard challenges

> Fab Tracker by MODS minimizes administrative burdens from the fabrication process with automated, transparent, mobile information-based workflows for unparalleled efficiency <

![]()

> Fab Tracker features <

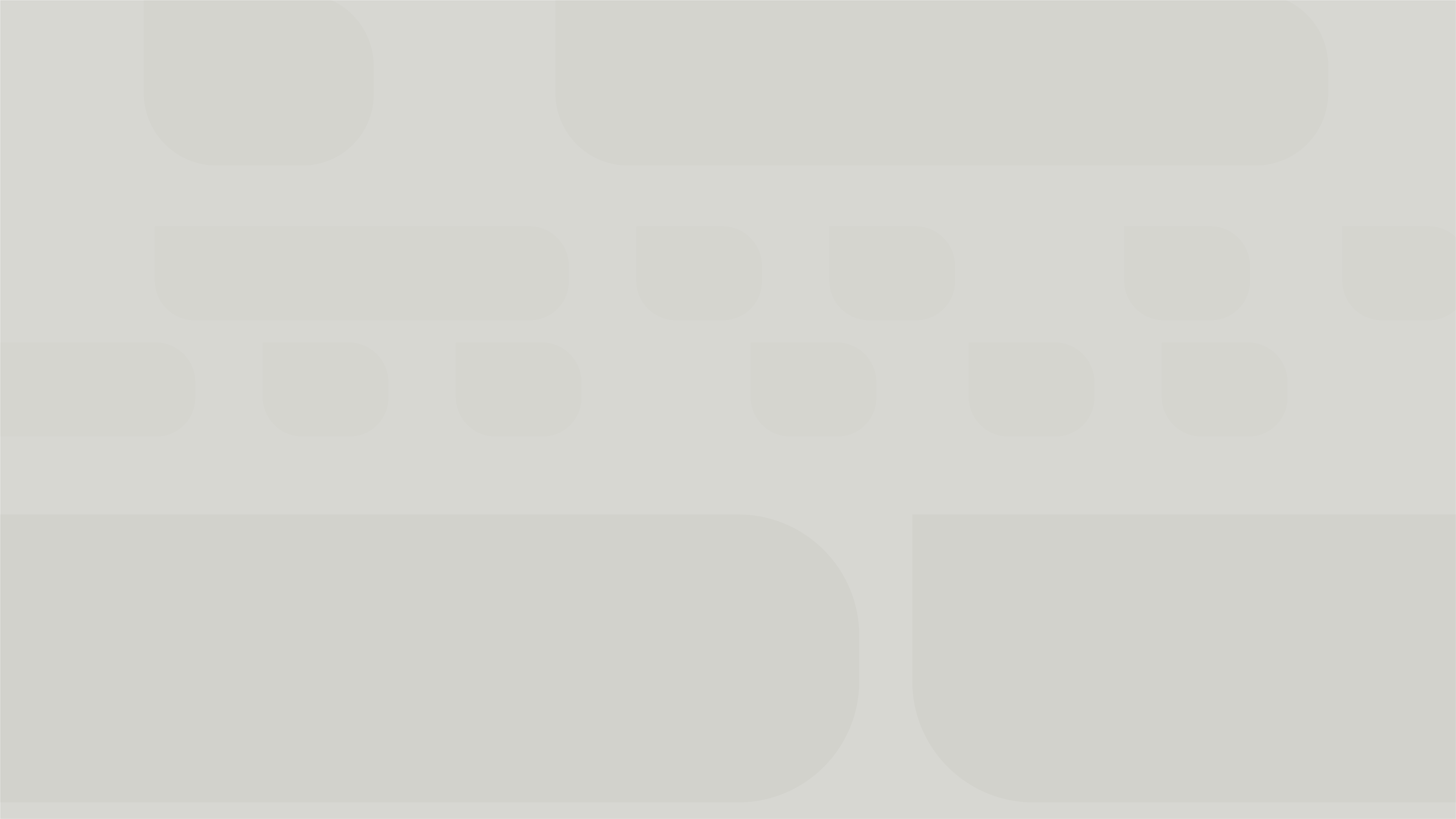

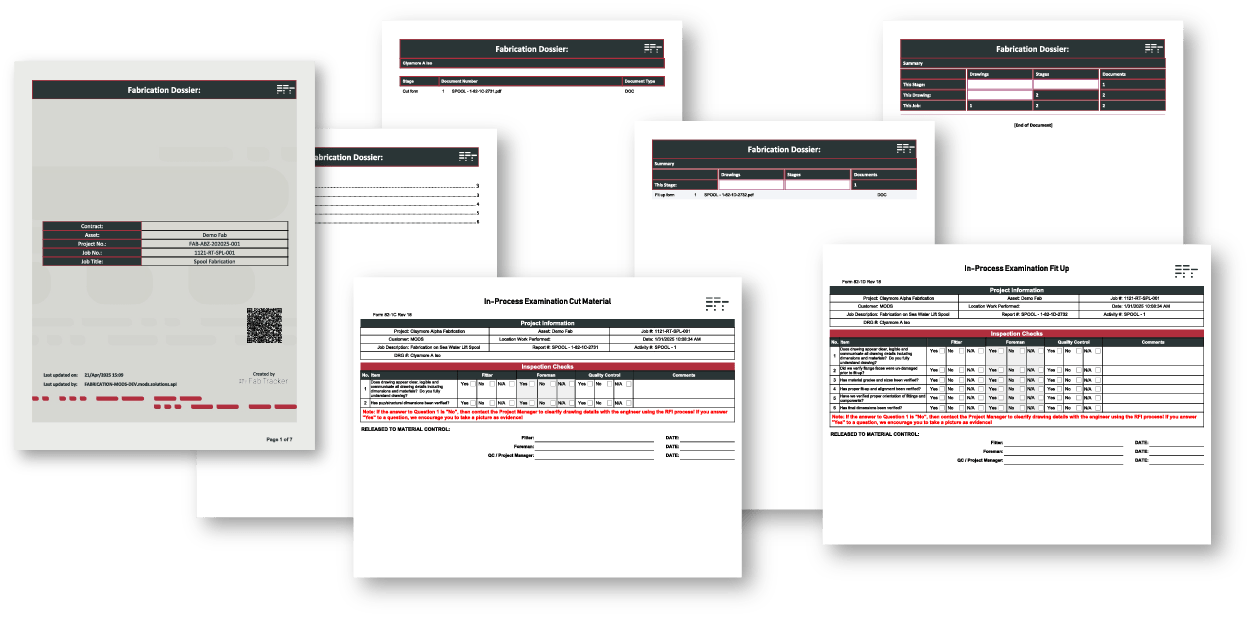

> Digital Fabrication Dossiers

Automatically generated fabrication dossiers eliminate time spent on administration.

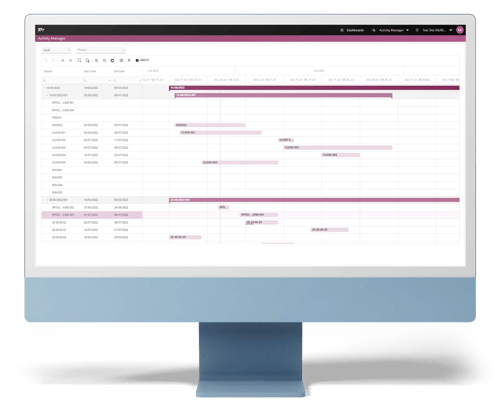

> Mobile App

Enables real-time component traceability with QR scanning via mobile devices, reducing dependency on paper or desktop-based tracking.

![]()

> Progress Tracking

Remove admin time from fabrication tracking. Features such as the digital markup tool and quality assured document management ensure full visibility of the entire process.

![]()

> Cloud-based System

Eliminates the need for additional IT infrastructure or support while ensuring data are accessible from anywhere, by anyone.

> Automated Reporting

Simplifies reporting and quality assurance, reducing administrative burdens.

> Common fabrication-process challenges

-

Information gaps

-

Unknown real-time status

-

Lack of traceability

-

Compromised quality assurance

-

Tracking Heat Numbers and fabricated components

-

Delays from incident troubleshooting

-

Compiling and managing fabrication dossiers

-

Real-time fabrication tracking via app technology

> Fab Tracker improves <

> Efficiency

> Cost

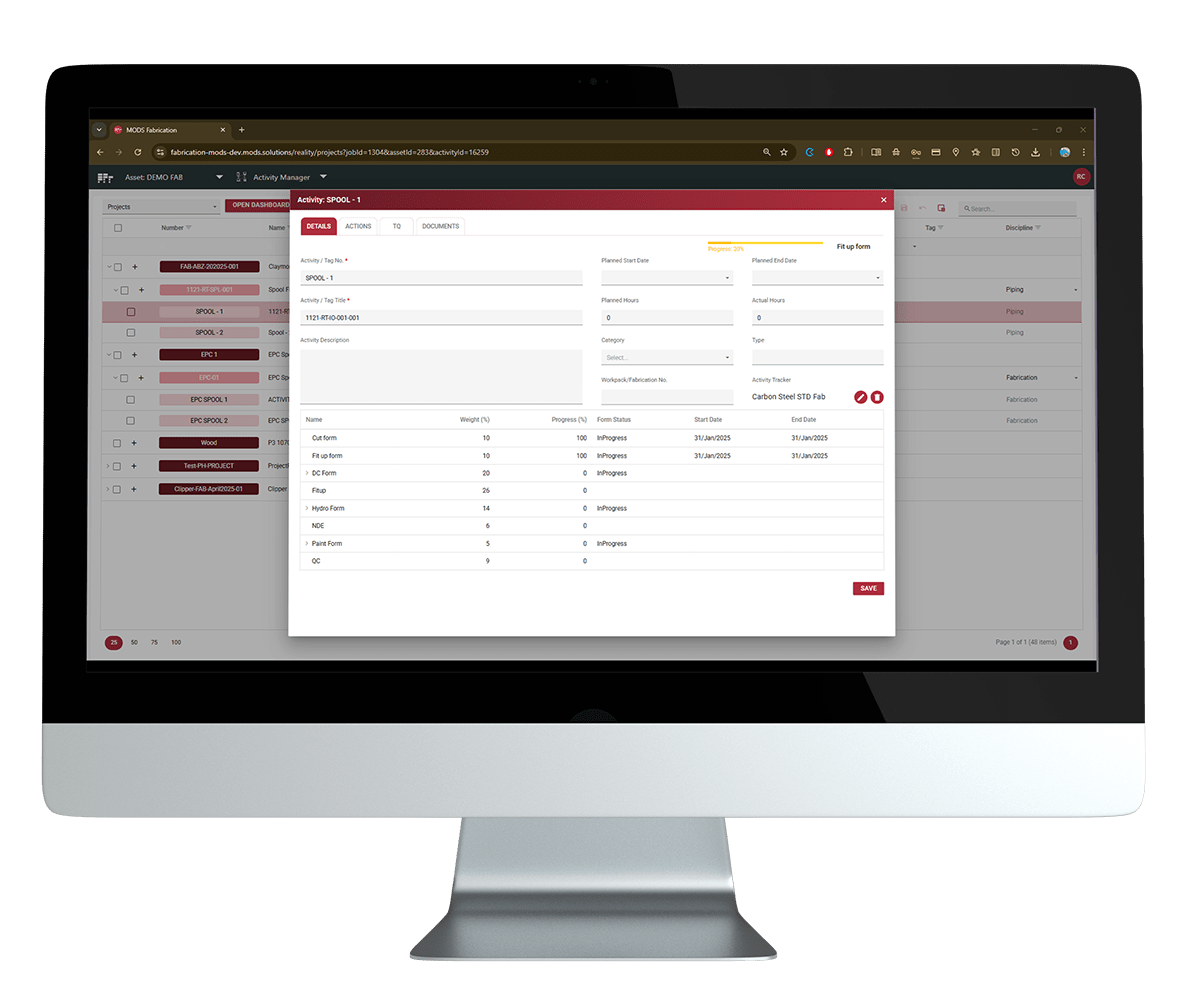

> Scheduling

> Productivity

> Traceability

> Communication

> Trusted by fabrication teams in the field <

“[It] is so much more than just a Fab Tracker. It’s a real time display of credibility, it’s just a bonus that it shows us every stage gate that the fabrication of that item is in. The ease of access to see a percentage of where your project is in fabrication is unbeatable. It’s going to revolutionise the way we have been doing reports for clients and for personal use. Super excited to see the road this takes GIS down in the future with all the new things MODS is constantly working to improve on.”

Fabrication Quality Assurance Manager

Grand Isle Shipyard (GIS)

> Fab Tracker benefits <

- Reduces errors and improves quality of the fabrication process

- Minimizes administrative processes to save time and money

- Minimal training required compared to traditional MES and ERP solutions

- Remote-enabled, live managerial overview

- Automated, transparent and accurate reporting

- Accessible mobile-first approach via an App available on any phone or tablet

- Prioritizes real-time tracking and activity management from the shop floor

- Increases productivity levels

- Enables proactive planning to reinforce schedules

- Anticipates bottlenecks in advance

- Improves project ROI

![]()

> Enhanced Visibility

- Enables proactive supply-chain management

- Reduces idle time and reactionary decisions

- Can link to digital work packaging systems to facilitate constraint-free

project execution - Eliminates project delays related to uncertain fabrication status

> Improved Traceability

- Eliminates risk of lost fabricated items

- Facilitates constraint-free project execution

- Enhances compliance and QA of fabricated components

- Ensures fabricated components are compliant and quality assured, reducing mistakes and defects

> Improved Project Efficiency

- Integrates with project management tools

- Streamlines communication and coordination

- Minimizes administrative delays

- Assures quality of information related to the fabrication process

> We would love to talk to you about

our digital fabrication solution <

MODS offers a digital fabrication solution, which is part of the MODS Connect suite. This drives automation of your supply-chain oversight, helping fabricators better align with your project phases. MODS Connect Fabrication gives you the ability to perform rapid incident tracing and to link with materials management systems as well as 3D project visualization. You will have live access to all essential fabrication information, supporting the delivery of projects on time and on or under budget.

Contact the MODS team to arrange a presentation on how MODS Connect can help your organization.