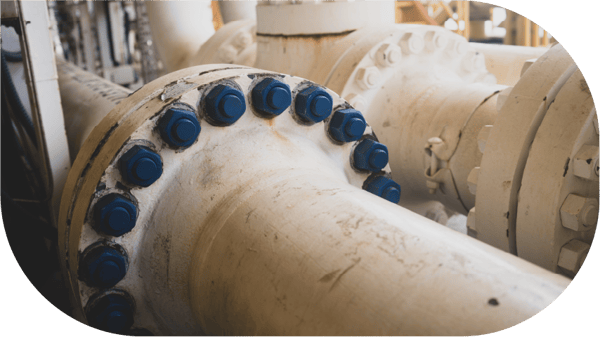

Avoid process leaks that threaten installations, employee safety and the environment with our digital integrity software.

> MODS Connect Integrity controls, validates, issues, tracks and indexes all bolted connections for quality-assured systems <

> MODS Connect Integrity

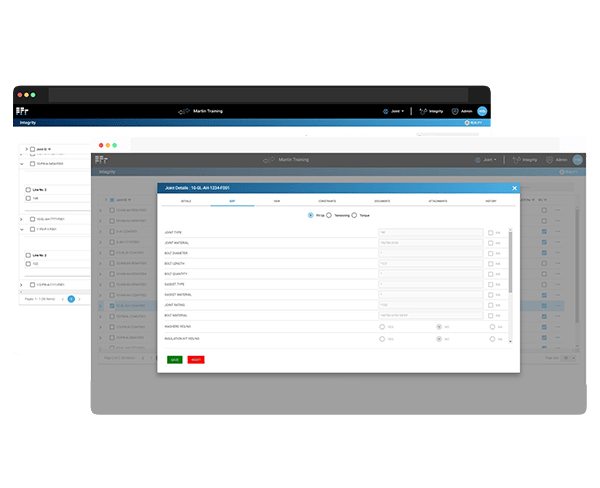

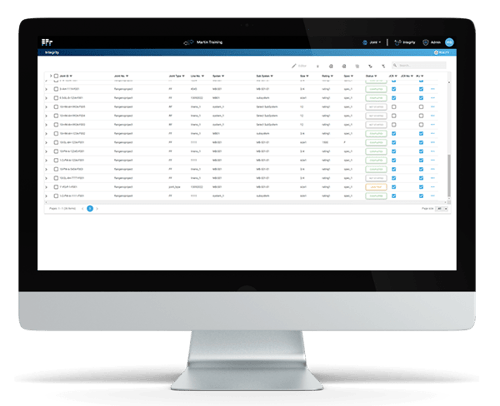

MODS Connect Integrity module is a cloud-based flange management software that uses QR codes and intrinsically safe handheld devices to control the processes associated with joint management and pipe systems testing, enabling users to track each joint online and in real-time.

> Integrity management challenges <

Current flange management systems, such as spreadsheet-based solutions and those that rely on paper-based printouts and spreadsheets, are time-consuming and prone to error, causing safety issues, losses and delays.

-

Lack of consistent procedures

-

Incorrect joint assembly

-

Wrong materials used for the job

-

Inadequate tracking of technicians' certifications

-

Inaccurate work progress updates

-

Missing tags

-

Improper tightening methods

> Digital integrity management improves <

> Industrial Health

& Safety

> Budget

> Compliance

> Production

> Project Schedule

> Client Relationships

> MODS Connect Integrity benefits

-

Transparent, accurate reporting

-

Reduced administration

-

Fewer business disruptions

-

Enforced regulatory compliance

-

Increased productivity levels

-

Dependable quality of work

-

Improved project ROI

-

Reinforced on-time schedules

> Digitalize your integrity system

Early adoption of a robust digital joint integrity system such as MODS Connect Integrity delivers cost efficiencies by avoiding process leaks that threaten employees, installations and the environment.

> Leak-free start-ups

MODS Connect Integrity eliminates leaking joints to mitigate risk and improve project delivery, avoiding any delays or rework. Leak-free start-ups reduce costs and keep projects on schedule.

MODS Connect Integrity ensures that contractors and sub-contractors have the necessary expertise, materials and planning in place to carry out bolting work for a safe, leak-free start-up.

> Real-time updates regardless of location

MODS Connect Integrity provides a seamless, collaborative, cloud-based solution utilizing handheld devices in the field to ensure joints are controlled safely, efficiently and on schedule.

> Thousands of reasons to digitalize your integrity management

In an average-sized petrochemical facility, there can be upwards of approximately 25,000 to 50,000 bolted flange joints - every one of which is a potential cause for a major catastrophe if not managed correctly. MODS Connect Integrity digitally manages this mammoth task for accountable quality-assured project delivery.

"Unfortunately, poorly executed joint integrity management has been the reason for significant past incidents causing millions of dollars' worth of damage and unacceptable fatalities. However, with the knowledge of the substantial risk, companies continue to conduct work without a truly accountable system related to bolted joints. Leaks from incorrectly assembled bolted joints during the construction phase and poorly pre-assembled components, are entirely avoidable if you digitize your systems allowing for accountability and real-time progress status updates.”

Jon Bell

CEO, MODS

> Digitalize your joint integrity processes

for operational excellence <

As a cloud-based joint management system, MODS Connect Integrity provides an affordable and easily adaptable solution for managing bolted joints utilizing handheld technology and automation. The system is designed to enable users to interact directly with the online database to efficiently track each joint, reducing errors and delivering accountability.

The MODS Connect suite delivers workflow efficiencies, saves money and delivers transparency and accountability in pursuit of operational excellence through the following:

-

Reducing schedules

-

Reducing resource costs

-

Providing full traceability

-

Improving safety

-

Increasing productivity

-

Enabling remote work

-

Ensuring dependable progress tracking

> MODS Connect Integrity functions <

-

Access control

-

Alerts / escalation

-

Audit trail

-

Automated email reporting options

-

Bolt tightening

-

Completed joint databases

-

Data import / export

-

Electronic signature capture

-

Mobile / handheld app

-

Historical data for each joint

-

ITR smart forms

-

Joint disassembly/breakout

-

Leak history

-

Rapid flange / joint entry import

-

Reporting

-

Search functionality

-

Test packs (Hydrostatic, Pneumatic, Nitrogen or Helium)

-

User control management

> We would love to talk to you about

our digital Integrity solution <

MODS Connect Integrity is part of the MODS Connect suite of intelligent industrial software solutions. MODS Connect delivers real value to your projects. The exponential cost of a major safety incident compared to putting an effective digital integrity solution in place is not comparable. At best, if the leak does not cause a major incident, the rework may cost several times more than the amount to do the initial work correctly.

Contact the MODS team to arrange a presentation on how MODS Connect can help your organization.

> USE THE FULL MODS CONNECT SUITE FOR HIGHER ROI <

> MODS Connect Integrity

MODS Connect is the overarching suite of software designed for the challenges faced by EPC groups and operators involved in any phase of industrial asset management or project execution.

MODS Connect Integrity integrates with the entire MODS software suite, but can also function as a stand-alone solution that can integrate with your existing systems. We recommend looking at the full MODS Connect offering for industrial projects and asset management.